Reliability

Analysis

Deep analysis and recommended actions to improve aircraft and component reliability.

The Reliability Analysis module in AVILYTICS is designed to provide aircraft operators with comprehensive tools to monitor and enhance the reliability of their fleets. By utilizing data-driven insights, this module helps identify potential issues, track performance, and implement preventive measures to ensure optimal fleet reliability and availability.

Function Highlight

Main Reliability Dashboard

Provides a summary of the most critical reliability metrics and trends across the fleet. Includes technical dispatch reliability, unscheduled removals, and defect rates.

Technical Dispatch Reliability:

AVILYTIVS measures the impact of technical delays and cancellations on overall fleet performance. Analyzing root causes of delays and cancellations to implement effective corrective actions.

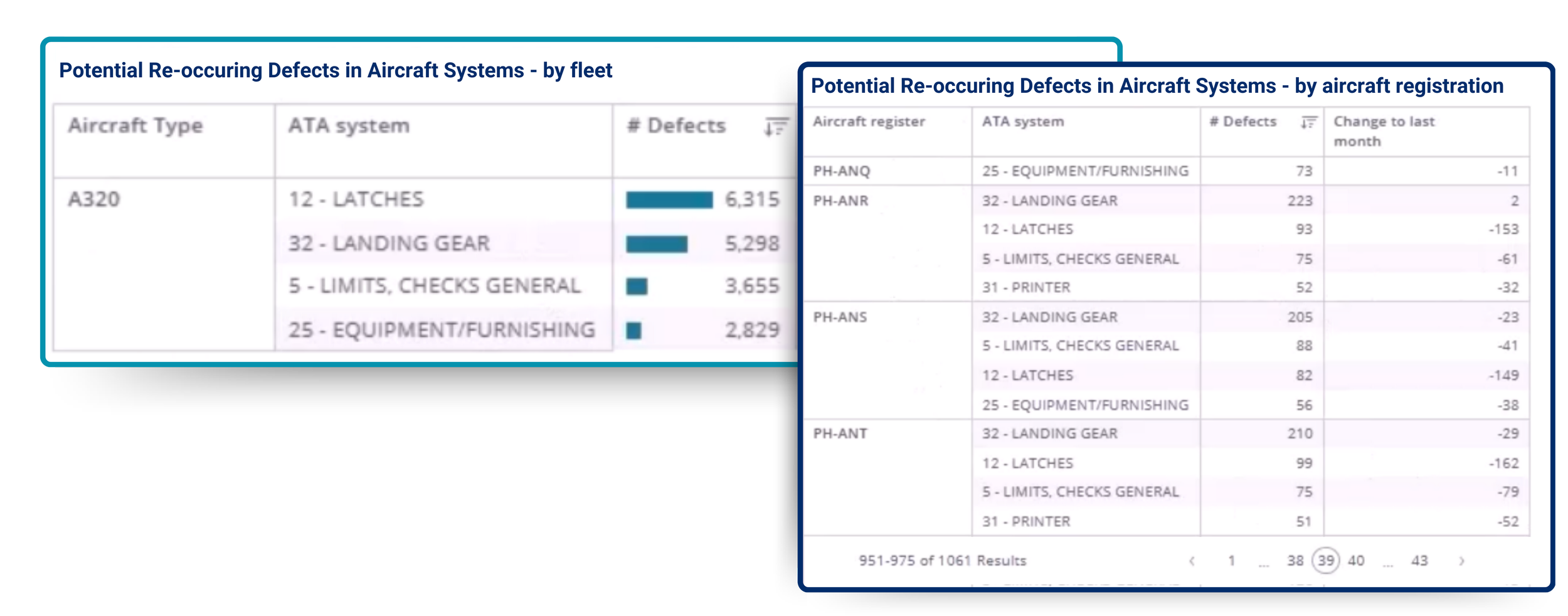

Defect Analysis and Forecasting

AVILYTICS identifies potential chronic defects in aircraft systems and uses historical data to forecast future defect trends.

how does it work?

Data Collection & Integration

AVILYTICS integrates seamlessly with various data sources within an airline’s operations, including M&E/MRO systems, flight operations data, and other relevant databases. This ensures a comprehensive collection of data necessary for accurate reliability analysis.

Data Processing

Collected data is processed and normalized within the AVILYTICS data warehouse. This step ensures consistency and accuracy, making the data ready for advanced analysis.

Interactive Dashboards

Interactive dashboards provide real-time insights into fleet reliability, allowing users to view overall performance and drill down for detailed analysis. Customizable widgets enable users to tailor dashboards, focusing on specific metrics like component failure rates, defect trends, or maintenance effectiveness.

Defect Tracking and Analysis

Defect Reporting

Tracks defects reported by pilots, maintenance crews, and cabin staff, categorizing them by ATA chapter and defect type.

Trend Analysis

Identifies trends in defect reports, helping to pinpoint systems with impaired reliability. Historical data is used to forecast future defect rates and identify potential chronic issues.

Maintenance Program Effectiveness

Task Distribution analyzes scheduled maintenance tasks across aircraft systems for a balanced workload and optimal scheduling. Interval Adjustment Recommendations optimize maintenance efficiency by suggesting task interval changes based on findings and usage patterns.

Deferred Defects Management

Monitors deferred defects, tracking reasons and trends to improve maintenance planning and execution. Identifies frequent deferral reasons such as no parts available, low manpower, or operational constraints.

ETOPS Compliance Monitoring

Tracks defects impacting ETOPS status and monitors engine and APU oil consumption to ensure compliance and early detection of issues. Provides root cause analysis for ETOPS downgrades.

Ole Holmsten, Head of Engineering at Norse

“We Are Excited To Work With EXSYN And Their AVILYTICS Software. We Have Just Started The Project, And What We Have Seen Already Is Impressive.”

Be Part Of The community

Explore all AVILYTICS Functions

Request a Software demo

Get a full demo of RELIABILITY ANALYSIS FROM AVILYTICS

See for yourself how it works and let us answer questions specific to your Engineering & Maintenance department.

hello@exsyn.com | +31 (0) 20 760 8200