Engineering &

Maintenance Analytics

Optimize maintenance processes and prevent late returns of aircraft from maintenance.

This module helps identify areas for improvement, track performance metrics, and ensure efficient and effective maintenance operation. By conducting detailed root-cause analyses, it identifies inefficiencies and procedural bottlenecks.

Function Highlight

Detailed Performance Analysis

AVILYTICS enables detailed investigations into the reasons maintenance teams may exceed the scheduled ground times for aircraft maintenance. By identifying the root causes of inefficiencies or delays, whether they stem from logistical issues, procedural bottlenecks, or external factors, the platform provides a basis for informed decision-making. Reports can be exported in PDF format, making it easy to share with relevant stakeholders.

Productivity Analysis

AVILYTICS Measures required manpower for maintenance, identifying factors that impact actual maintenance manpower required and areas for productivity improvement.

Main Driver Identification

Through the analysis, AVILYTICS pinpoints the main drivers behind maintenance delays. This could include specific components that frequently fail, inefficiencies in maintenance planning workflows, or delays in parts supply. Understanding these drivers allows for targeted interventions.

Interactive Data Visualization

Users can drill down into specific data points for more detailed analysis. They can apply filters to view data by aircraft type, maintenance station, date range, and more.

how does it work?

Data Collection & Integration

AVILYTICS integrates seamlessly with various data sources within an airline’s operations, including M&E/MRO systems, flight operations data, and other relevant databases. This ensures a comprehensive collection of data necessary for accurate maintenance operation analysis.

Data Processing

Collected data is processed and normalized within the AVILYTICS data warehouse. This step ensures consistency and accuracy, making the data ready for advanced analysis.

Interactive Data Visualization

Interactive dashboards provide real-time insights into maintenance and engineering performance, allowing users to drill down for detailed analysis. Custom filters enable focusing on specific aircraft types, maintenance stations, date ranges, and other criteria to isolate and analyze aspects of maintenance operations.

Performance Metrics Calculation

Work Order Deassignment Reasons

Tracks the reasons why maintenance work orders have been deassigned, providing insights into the efficiency and effectiveness of maintenance teams.

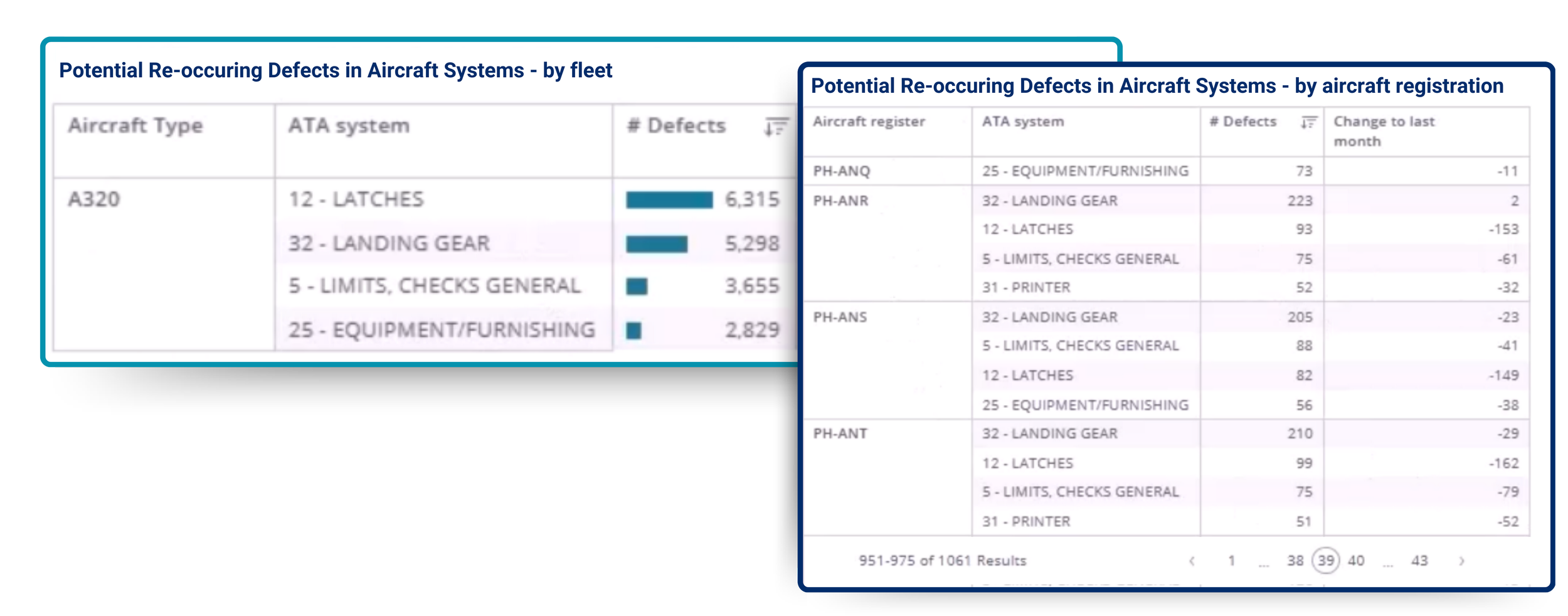

Deferred Defects Analysis

Monitors deferred defects, tracking reasons and trends to improve maintenance planning and execution.

Automated Reporting and Alerts

Schedule automated KPI reports and distribution for timely access to critical data. Set up Pulse notifications for KPI metrics, such as workorder deferrals, AD-SB completion, or AOG on a station.

Ole Holmsten, Head of Engineering at Norse

“We Are Excited To Work With EXSYN And Their AVILYTICS Software. We Have Just Started The Project, And What We Have Seen Already Is Impressive.”

Be Part Of The community

Explore all AVILYTICS Functions

Request a Software demo

Get a full demo of ENGINEERING & MAINTENANCE KPI FROM AVILYTICS

See for yourself how it works and let us answer questions specific to your Engineering & Maintenance department.

hello@exsyn.com | +31 (0) 20 760 8200