How Predictive Maintenance Enhances Aircraft Performance and Reliability

Explore how predictive maintenance transforms aircraft maintenance by using real-time data to anticipate issues, improve safety, and reduce costs, ensuring greater reliability and performance. Explore emerging technologies and industry trends that make predictive maintenance the cornerstone of modern aviation strategies.

The Impact of Data Quality on Aircraft Safety

Data quality is essential in aviation, ensuring data accuracy, consistency, and relevance for effective airworthiness management. High-quality data supports compliance automation, predictive maintenance, and optimized inventory management, enhancing safety and operational efficiency. Poor data quality can lead to maintenance errors, regulatory noncompliance, and increased safety risks. Implementing stringent data quality checks and using advanced software solutions like NEXUS can significantly reduce maintenance costs and improve overall efficiency.

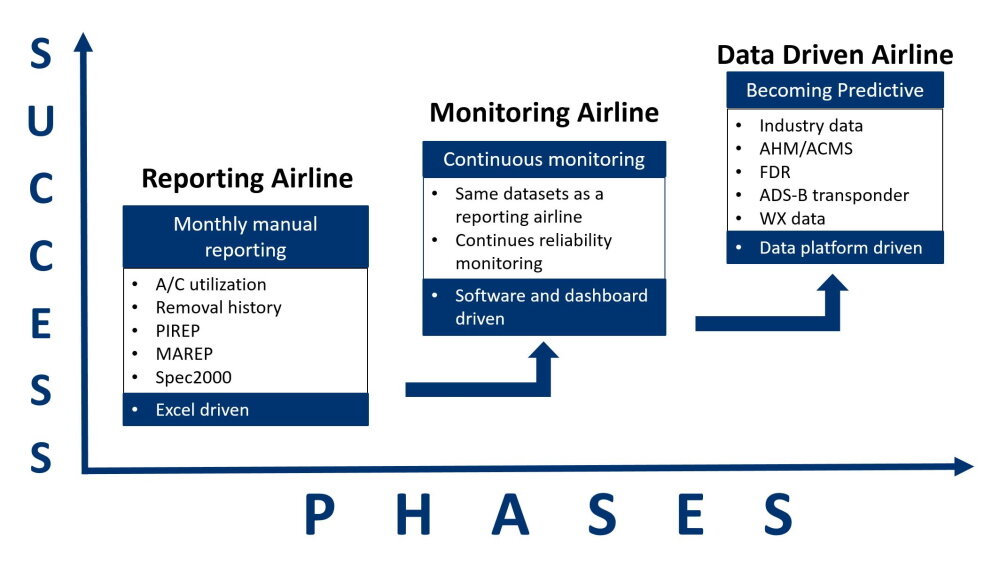

Data-Driven Aircraft Maintenance: How to get there?

Discover how improving safety, effectiveness, and reliability through data-driven maintenance can transform the aviation industry. Learn how to overcome data quality and integration challenges, integrate and analyse data for predictive maintenance, and reap the benefits of maximising aircraft utilisation and minimising unplanned maintenance.

Data Management Best Practices for Aircraft Maintenance

With the increased usage of more advanced technologies and new aircraft, data has become a key player in enhancing aircraft maintenance practices. Thus, the importance of effective data management is increasing as well and is crucial for ensuring the safety, reliability, and efficiency of aircraft operations. Aircraft maintenance relies heavily on accurate and timely data to make informed decisions and keep fleets in optimal condition. Therefore, today we will outline the key essentials to be able to make optimal use of data and the benefits of it for aircraft maintenance

What MROs Can Gain from Predictive Maintenance

Explore how Maintenance, Repair, and Overhaul (MRO) organisations can implement Predictive Maintenance to enhance efficiency and reduce costs. Learn about the similarities and differences with commercial airlines, key considerations, and practical steps for successful implementation.

How to maximize the benefits of Predictive Maintenance in Aircraft Maintenance

Aircraft maintenance is a crucial aspect of aviation, as it ensures the safe and efficient operation of aircraft. Predictive maintenance offers significant benefits such as reduced downtime, and costs.

Learn more about how to maximize the benefits of predictive maintenance

Video - Short Introduction to the Different AVILYTICS Workspaces: Reliability Management Logistics, E&M KPI, AOG Risk Monitor

Short introduction video of the different workspaces within AVILYTICS

How to manage Aircraft Flight Statistics simple and efficient?

Aircraft flight utilization and statistics have a pivotal role in determining which variables in the aircraft maintenance program need to be followed.

How to gain meaningful understanding in the reliability of components installed in the aircraft?

Unscheduled Component Removals - Aircraft component reliability is a significant underlying contributing factor for dispatch reliability. In this blog you learn how to gain meaningful understanding in the reliability of components installed in the aircraft.

AOG risk monitoring, what is it and why does it matter?

An Aircraft On Ground (AOG) event is one of the most costly occasions within any airline operations. An unexpected technical defect on an aircraft can result in increased downtime.

How to monitor and forecast your maintenance and engineering costs simple to achieve cost savings?

Now more than ever it has become elemental to control ongoing maintenance costs in airlines. Once the annual maintenance budget is set, many factors can influence deviations from this allocated maintenance budget

How to ensure that outcomes of repeated defect analysis provide meaningful results

Having the ability to identify potential repeating defects on an aircraft can greatly contribute to increasing the overall fleet availability of any airline. How can you ensure that outcomes of repeated defect analysis provide meaningful results?

How to start with data analytics in aircraft maintenance although much information is still paper based?

How to start with data analytics although much information is still paper based? 5 Min Read